High Speed Petri Dish Filling

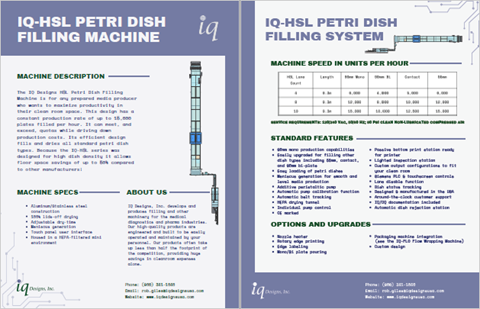

Our dedicated petri dish filling machines can be optimized for 90mm, contact/RODAC plates, 55mm and more. By focusing on one or two dish types speeds of up to 1,500 dishes per hour, per lane can be reached, far faster than the industry standard.

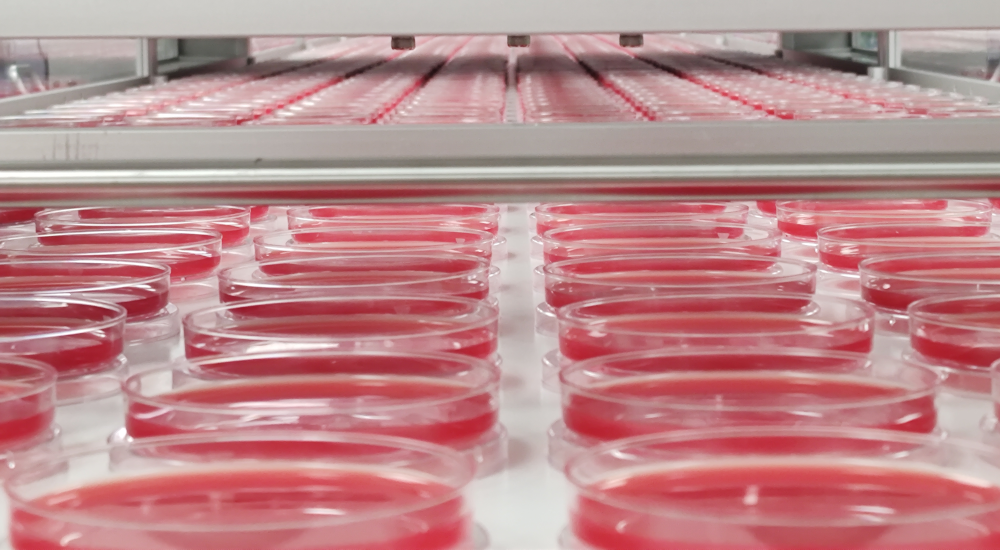

A standard 8-lane HSL machine can fill up to 12,000 dishes per hour with extremely efficient use of belt space, saving you floor space and production time. Because these machines dry product with covers fully removed the entire media surface is exposed to the same drying conditions for the entire time spent on the cooling belt.

Our petri dish filling machines can be used with many different products like diagnostic culture media, tissue culture, agricultural filling processes and anything else that requires filling of Petri dishes. Production rates on our machines are based on a three-minute dry time and more time can be added as needed. We provide custom configurations as needed. If multiple dish types need to be used with the same machine please explore the MX000 series machines.

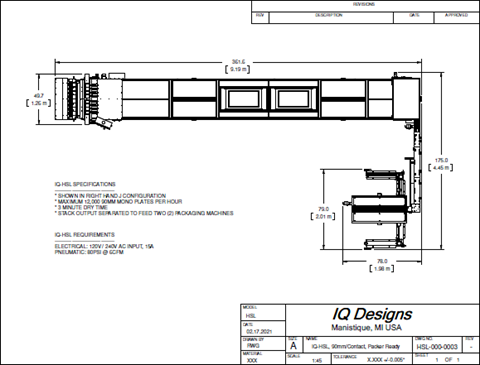

IQ-HSL: Our fastest filling machine

This is our highest speed petri dish filling machine which has a space-saving design that can take up less than half of the footprint of the competition. With 100% open dish drying, all enclosed in a HEPA-filtered environment, your product will be evenly dried and protected from the environment. The IQ-HSL provides maximum dish density while allowing consistent drying and the machine layout can be customized to your unique needs. High-speed stacking using our drop stacking technique avoids stack tip-over and other problems found with conventional stackers. This machine is an integral part of a high output petri dish filling system.

Standard Features

- Enclosed HEPA drying environment

- Individual pump control

- 100% open lid drying

- Adjustable dry time

- Bottom print station

- Multi-cavity orientation where applicable

- Additive pump where applicable

- Meniscus generation where applicable

Optional Features

- Nozzle heating

- Bulk loader

- Passive edge printing

- Rotary edge printing

- Edge labeling

- Packaging

| HSL Lane Count | Length | 55mm | Contact | 90mm Mono | 90mm Bi |

|---|---|---|---|---|---|

| 4 | 9.3m | 6,000 | 5,000 | 6,000 | 4,000 |

| 8 | 9.3m | 12,000 | 10,000 | 12,000 | 8,000 |

| 10 | 9.3m | 15,000 | 12,500 | 15,000 | 10,000 |