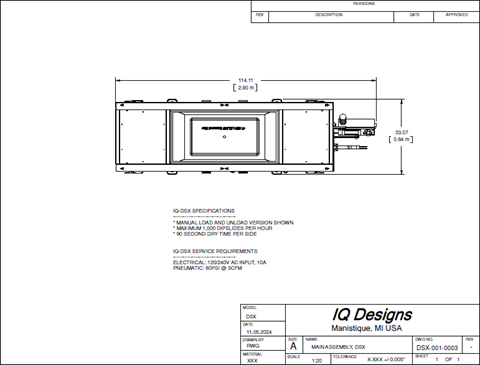

Dipslide Filling Machine

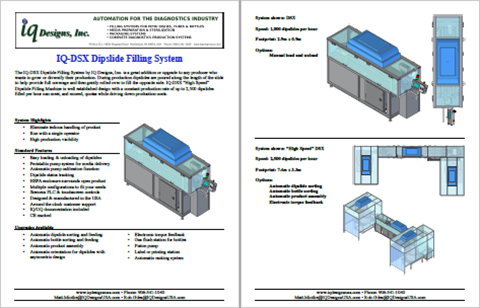

The IQ-DSX dipslide filling machine automatically fills and dries both sides of dipslides automatically. From a small manual load and unload system to the larger, fully automated system, our dipslide filling equipment does the tedious work for you. We have worked with many kinds of dipslides including the standard round cap to odd-shaped outside threaded caps.

IQ-DSX: Dipslide filling made easy

The IQ-DSX dipslide filling machine features easy loading and unloading along with a simple and reliable slide flipping method. Pouring on both sides of the slide is easily accomplished and the result is a fully completed product, ready to package. With options to add product orientation, automatic dipslide and bottle descrambling, and assembly this is a fully capable dipslide production system.

Standard Features

- Single and multi-cavity pouring

- 90 second dry time each side

- Media delivery through use of peristaltic pumps

- Small footprint

- Touch panel user interface

Optional Features

- Automatic orientation of multi-cavity slides

- Automatic dipslide sorting

- Automatic bottle sorting

- Automatic product assembly

- Electronic torque feedback

| DSX Model | Dipslide Type | Speed |

|---|---|---|

| Single lane | Single/Multi-cavity | 1,000 |

| Dual lane | Single/Multi-cavity | 2,500 |